Hello,

I build an AI model that creates trajectories for a 3DOF Delta Robot. I trained the model based on a digital twin of this robot and know that the created trajectories should be possible.

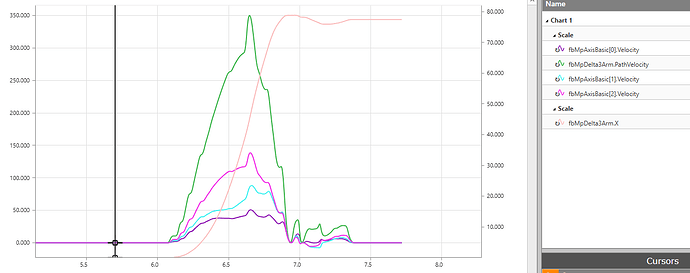

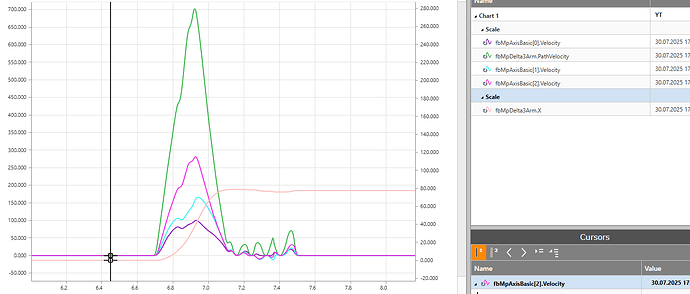

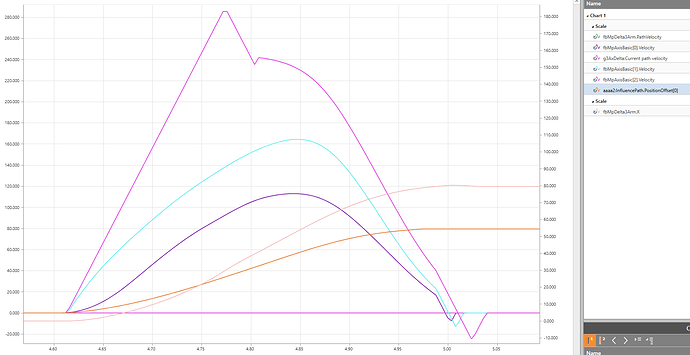

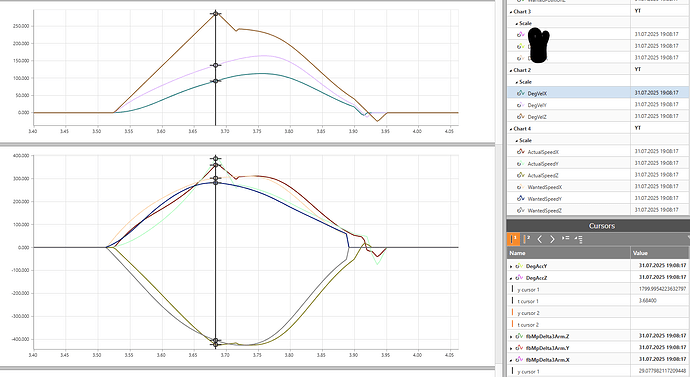

Now I want to replicate the trajectories on the real robot, but I can’t figure out how to get a smooth trajectory with correct velocities and accelerations.

Is there any way to do this?

Information about my setup:

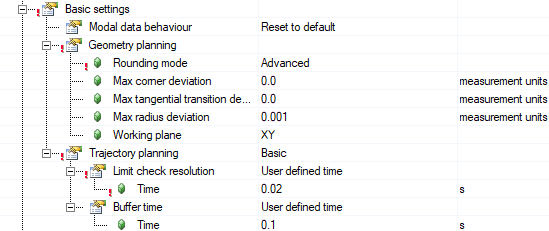

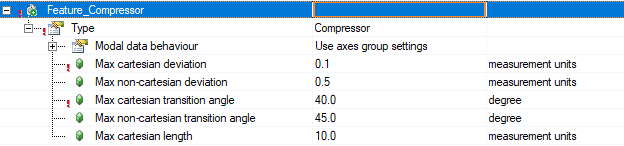

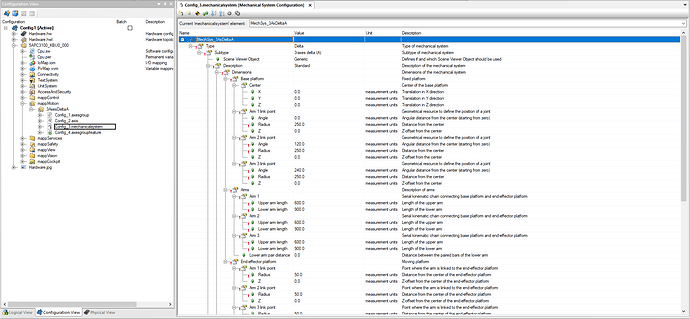

- I use mappMotion

- I use the mapp Robotics 3-Axes Delta (A)

- Information provided by my trajectory is: time, acceleration_x, acceleration_y, acceleration_z, velocity_x, velocity_y, velocity_z, coordinates_x, coordinates_y and coordinates_z.

- The time between each trajectory point is 20 ms

- My main CPU cycle is 4 ms

- I use a synchronous motor

I tried ST-Motion Commands, but this only gets me the right position but not velocity or acceleration.

I also tried using GroupJog and setting max acceleration and desired velocity to get the correct position after the 20 ms, but my desired velocity and the actual velocity reached after 20 ms are different somehow.

Is there maybe a way to just set position and time and let the PLC handle the rest?