Hello,

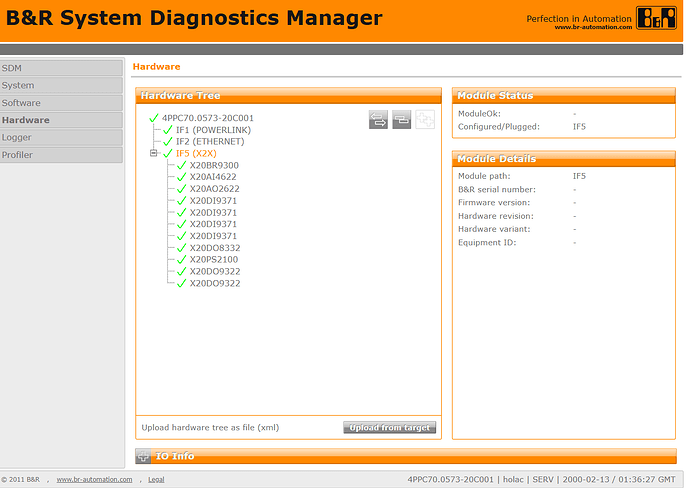

I’m reaching out regarding an issue with one of our B&R modular PLCs “4PPC70.0573-20C001”. During normal machine operation, the PLC suddenly rebooted by itself and got stuck in BOOT mode: Service, even though nobody intentionally activated this mode.

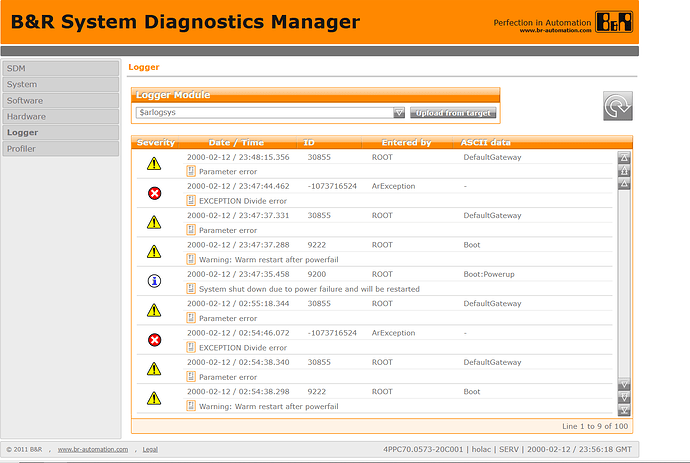

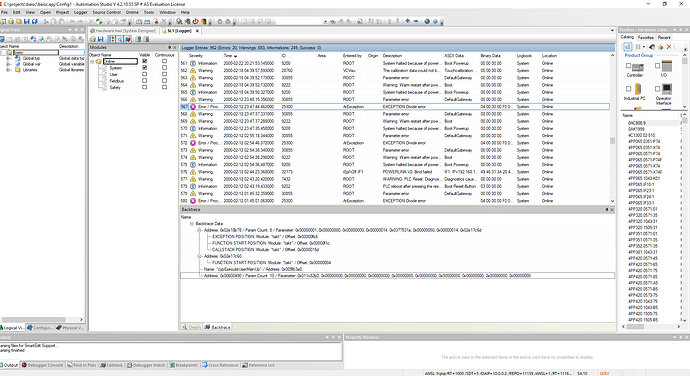

I’m quite new to B&R PLC systems, but after reading various forums, I tried to connect to the PLC using Automation Studio 6 and 4.2 to check the logs via the Logger and find out why the machine can’t fully boot. Currently, the machine starts loading, briefly reaches the main menu for a second, then reboots again and ends up stuck in BOOT mode: Service.

I managed to connect to the module over Ethernet, changed the Subnet Mask in Windows Ethernet settings and the module was detected. I then connected to it and tried to use “Open Project from Target”, but I received the following error:

*No valid Automation Studio project file!

*

After that, I tried creating a new project and running hardware identification, but I got:

No hardware information found

This happens while the PLC is in BOOT mode: Service

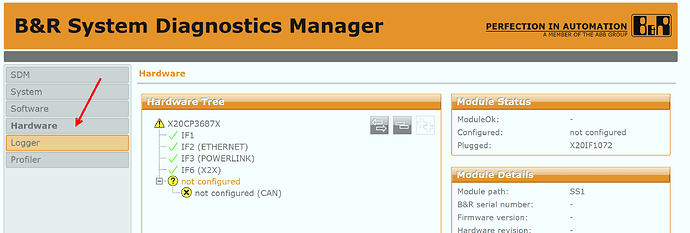

If I switch it to BOOT Mode: Diagnosis, the module shows up differently (IP and Subnet Mask become 0.0.0.0). I manually changed the IP and Subnet Mask in Automation Studio so I could connect - that part worked fine. However, when I repeated the steps (Open Project from Target), I got the same “No valid project file” error. When I tried hardware identification again, I received:

Hardware upload finnished with errors

Error 4808: No connection available to the PLC.

At this point, I’m not sure what the next step should be. Do you have any recommendations on how to properly connect to the PLC or recoved it from this BOOT mode: Service state? Is there any way to view logs or diagnose what caused the intial reboot, or does this indicate a hardware failure? And also Automation studio detects the boot mode when is it in service or diagnosis mode.

Thank you very much in advance for your help.

Best regards,

Konstantin Bobrovs