Hi there

The setup is as follows:

- arnc0

- optimizer (optmot)

- Axle group with 4 axles

The core currently calculates a path in which all axes arrive at the target point at the same time. Is there a possibility that all axes move with the maximum settings specified by the optimizer and thus no longer arrive at the destination at the same time?

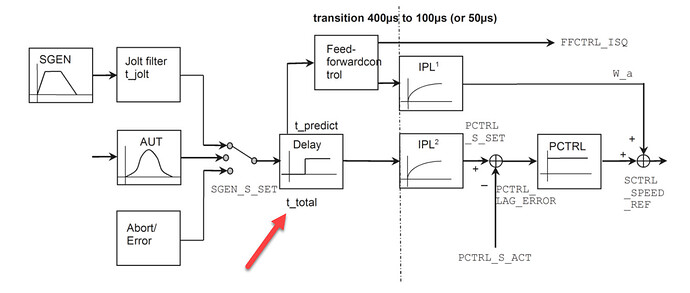

I can imagine the situation were the axis are in different networks and/or the parameters

POS_CTRL_T_PREDICT and POS_CTRL_T_TOTAL

are not well configured.

For instance, one drive has a different parameter that the rest, and this one arrives always late in comparision with the other 3.

B&R Online Help (br-automation.com)

Other option, is that the drives are in different POWERLINK networks

Hi Marcos

You might have misunderstood my question. The goal is exactly that. All axes in the group should move at the maximum configured setting and thus no longer arrive at the destination at the same time  .

.

Cheers

Therefore…the idea cold be

1-dissable the axis group

2-move all the axis as independent motors

3-move them as fast as possible

4-re-engage the axis group

Hi @Patrick_Schmitter! Does this suggestion solve your use case?

Hi Marcos

This sounds like quite some work for what I planned on using this. Since you didn’t just tell me an “easy way” of doing this I guess this might be the only way.

Thank you for your answers and ideas

Patrick